DISCOVER OUR PRODUCTS

INDUSTRIAL LABELING SYSTEMS

CHOOSE EXACTLY WHAT YOU NEED

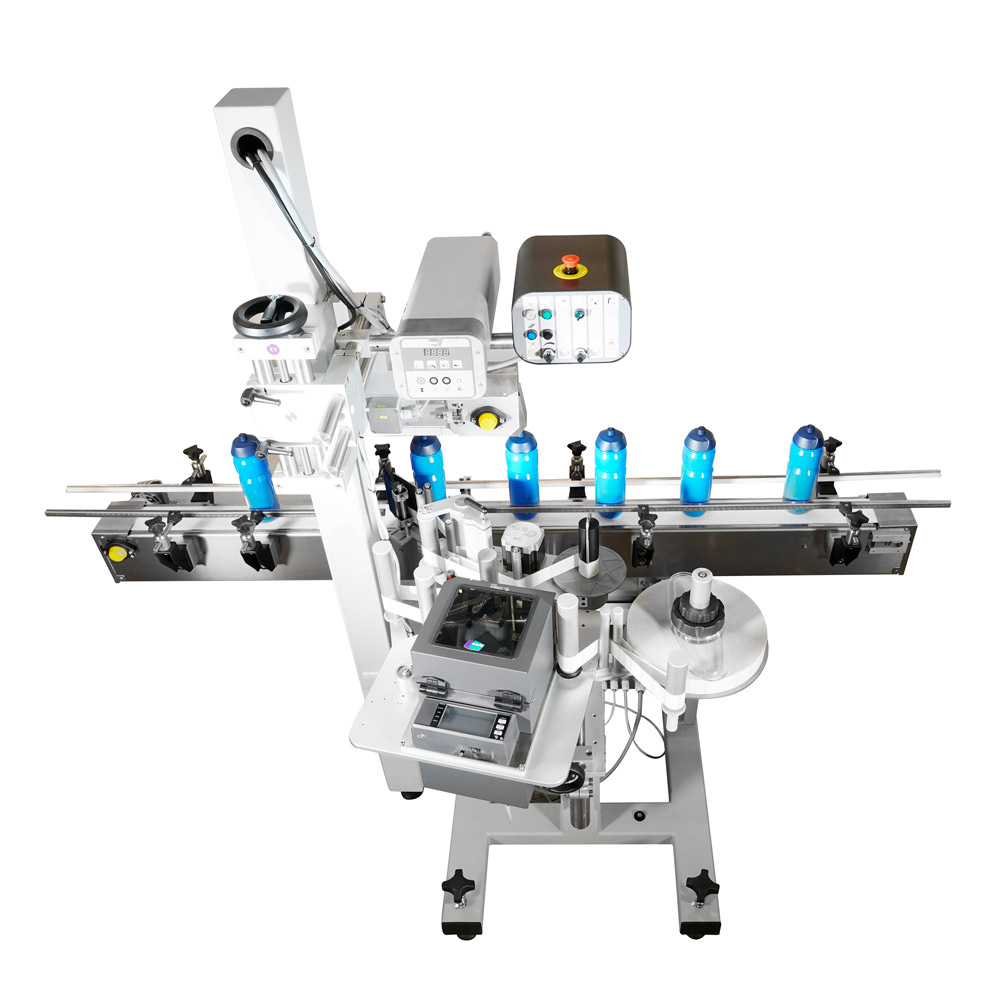

“Linear” labeling systems that guarantee all the flexibility of the self adhesive market.

No glue to feed in, heat or clean up.

Above all very quick “set up”, without the need for the replacement of mechanical parts (format changes) typical of rotary handling.

Different needs, different models to choose.

DISCOVER OUR PRODUCTS

INDUSTRIAL LABELING SYSTEMS

CHOOSE EXACTLY WHAT YOU NEED

“Linear” labeling systems that guarantee all the flexibility of the self adhesive market.

No glue to feed in, heat or clean up.

Above all very quick “set up”, without the need for the replacement of mechanical parts (format changes) typical of rotary handling.

Different needs, different models to choose.

Industrial Labeling Systems

Industrial Labeling Systems

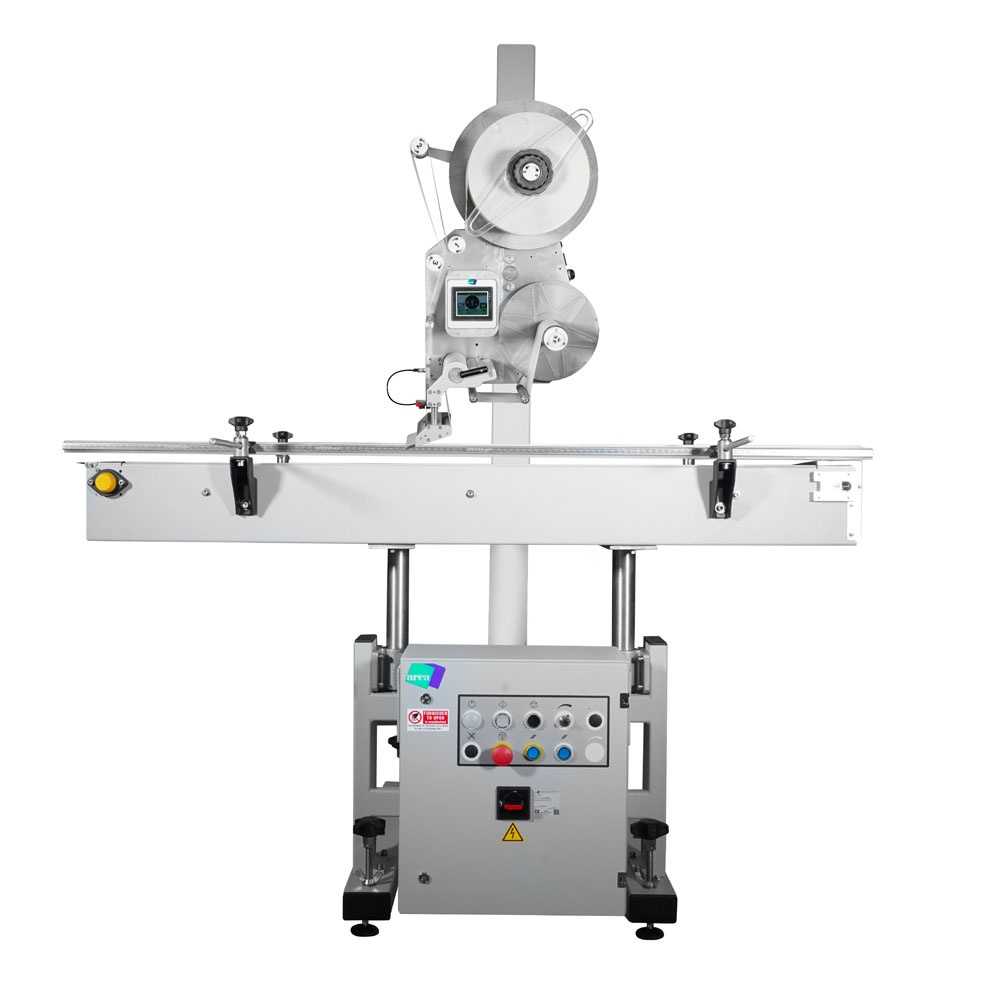

LIGHT SERIES

Minimum space, maximum efficiency. All the reliability of the simplest solutions, without jeopardizing quality.

Compact and simple machines that can be integrated both in automatic and off-line production lines with manual loading and unloading.

Efficient, simple and reliable industrial systems: no compromise with quality.

Available both Steel and Stainless Steel.

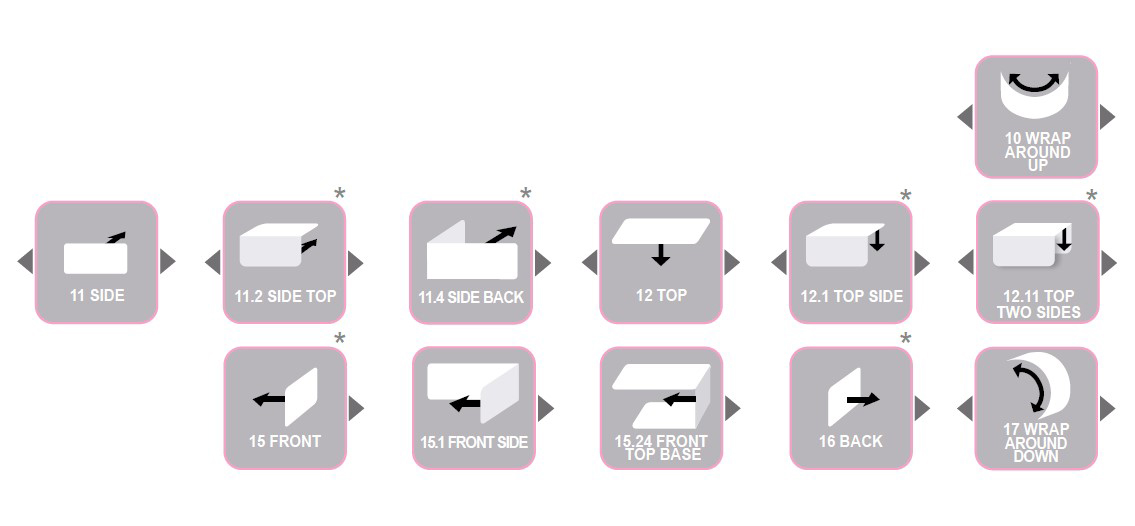

Possible application with LIGHT labeling machines for self-adhesive labels

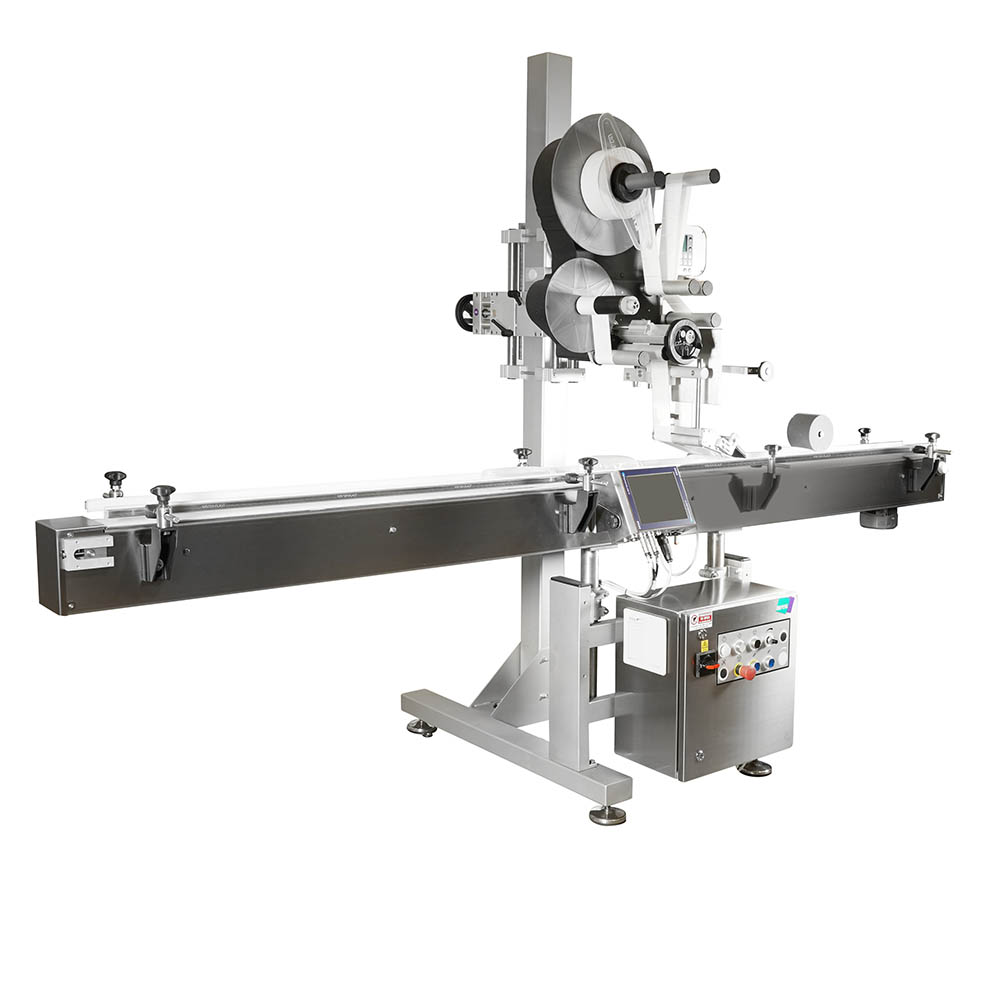

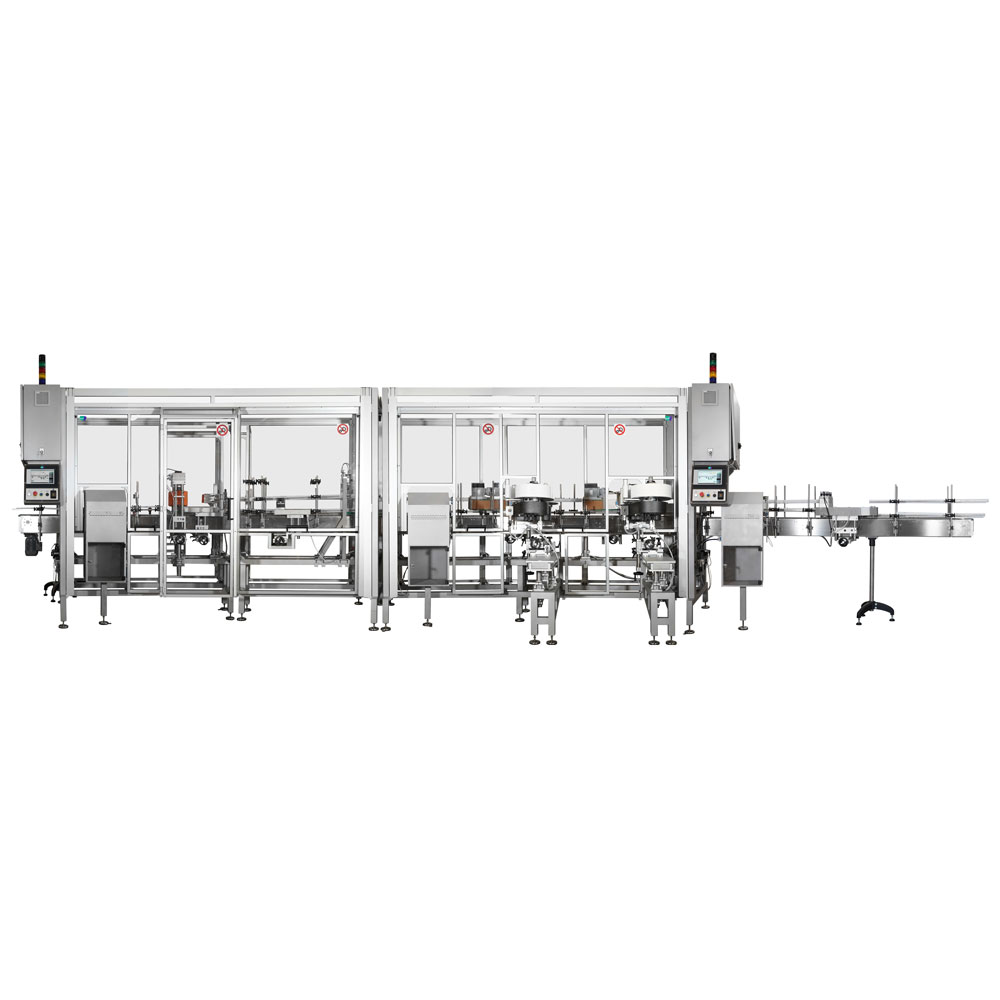

SOLID SERIES

Highly robust and expandable systems, with the possibility of placing the labelers on both operating sides.

The Solid series offers all the advantages of the Light systems as well as:

- in the Side configurations, labelers positioned on the operator side, to simplify the periodic deplated label roll change

- color display or graphical interface on industrial PC

- Combi configuration

- very high productivity Non Stop configuration

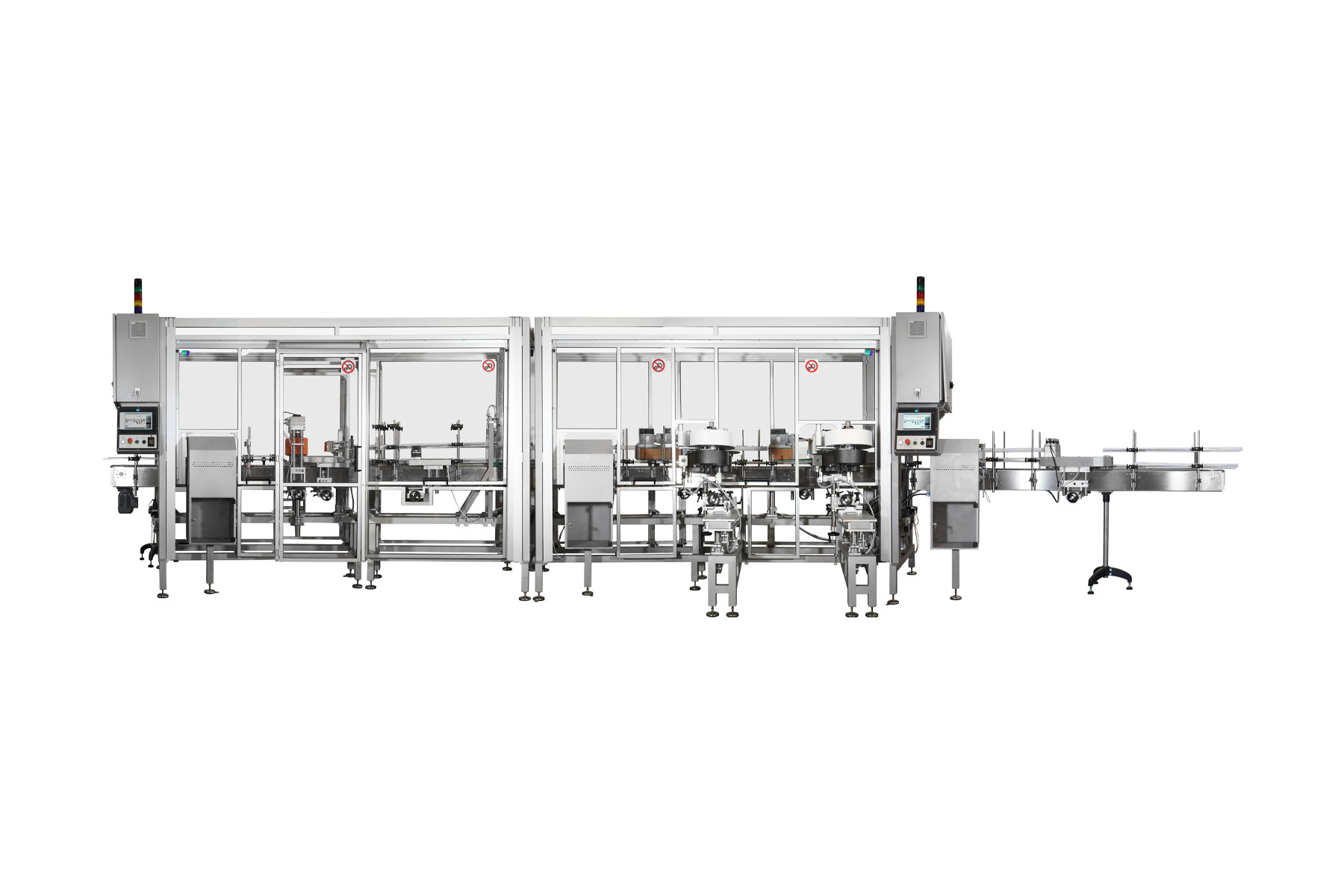

SKYTECH AND HIGHTECH

Highly robust and expandable systems, with the possibility of placing the labelers on both operating sides.

Models with the “uplifted” electrical system cabinet, near the power supply.

To wash and clean more freely. Even in the Low-Level version with the worktop particularly low, to allow the easier operation on lines that deal heavy products.

“Sliding door” protection (upward opening).

Available for all the Solid systems (Side labeling). For the least obstruction and to avoid any obstruction to the MMI when doors are opened.

It protects the system from dust and reduces noise pollution. The reel housing is accessible even with the covers down.

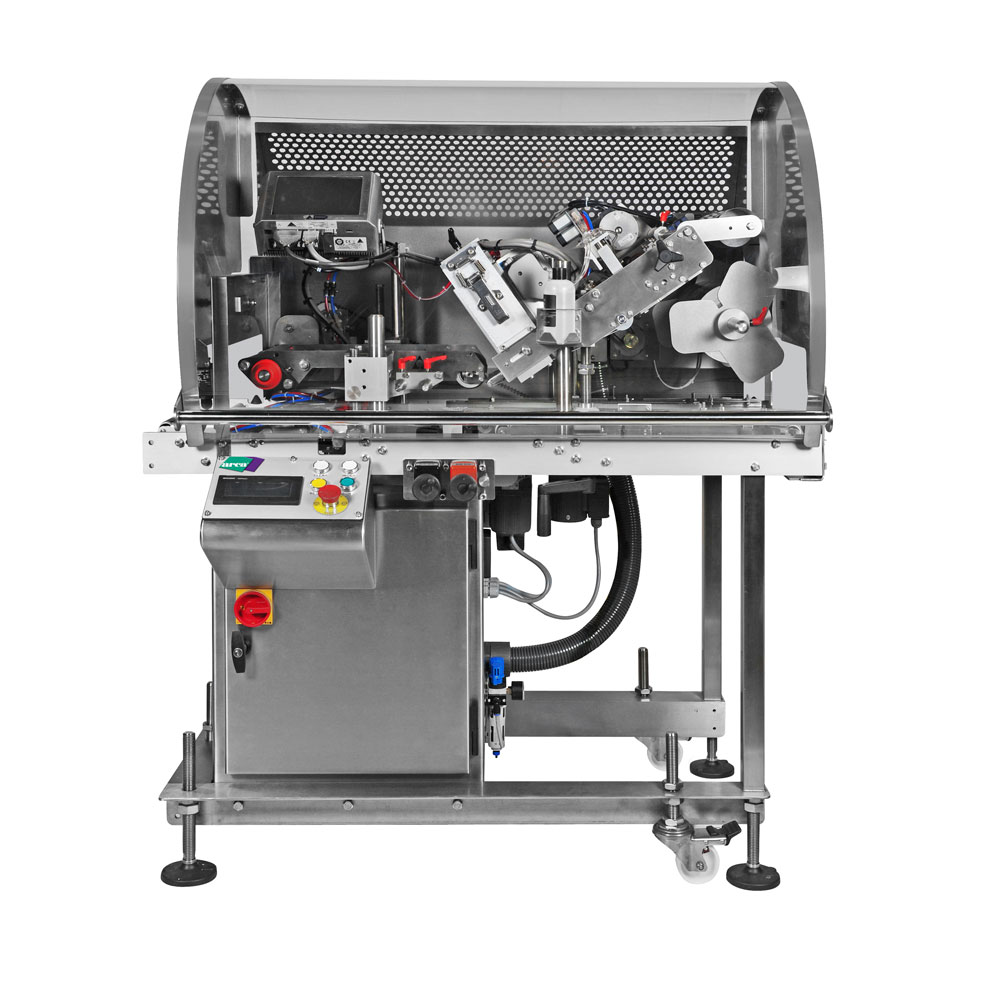

SPECIALIZED SERIES

Specialized systems to go through a specific task

- FEEDER: a labelling machine for labeling and/or coding flat products: laid down packets (either already glued or still “open”), telephone and credit cards, membership cards, envelopes, hang tags for clothing, etc.It allows for application on the upper surface of the product. Its modular main base in AISI 304 stainless steel can be equipped with: a labeler (with possible letterpress marker or digital coder), or ink jet print module of the thermo graphic type (HP technology) code scanners or vision sensors, for checking printed data and actual labelling

- STRIPED LINERLESS: A system for the ecological labeling of trays, containers and rectangular and parallelepiped products. It allows for application on the upper surface, sides and base of the product.

- CONVERTER: Converter labelling system is a Top application for any flexible continuous ribbon (film, labels, cardboard, etc.). Top labeling system (top feed) for any flexible continuous ribbon (film, labels, cardboard, etc.). The DP version is equipped with a T.T. desktop printer for basic label customization.

Pharma line

Labelling machines dedicated to the pharmaceutical industry for labeling, coding, traceability and aggregation of cartons, vials, bottles, single-dose strips and blow fill seal.

COMPACT 4.0

Automatic industrial pharmaceutical labeling system for wrap-around label application on ampoules, vials, test tubes, syringes, single-dose, strip monodose, blow fill seal and all cylindrical-format pharmaceutical products.

Arca designs a full range of automatic labeling systems for wrapping applications on pharmaceutical cylindrical products that can be used both offline (a rotary table is available for loading and unloading products) and on-line connected to other packaging machines (eg. filling machines) for applications from 10 up to 300 pieces per minute.

The labeling machine belongs to Arca Pharma labeling machines line: a specific line designed and dedicated to the labeling, coding, traceability and serialization of pharmaceutical products. Therefore, designed to guarantee high standards of quality, safety, productivity and accessibility provided by the guidelines on good pharmaceutical manufacturing practices.

For product traceability, the labeling system can be integrated with an Inkjet marker or a laser marker designed by Arca. The laser marker guarantees considerable advantages in terms of performance (non-stop solution), efficiency and operating savings.

PHARMATRACK SEAL 4.0

Serialization, Tamper-Evident Seals Labelling Track & Trace

Automatic industrial labeling system for traceability, serialization and tamper-evident seal labels application on the corners of pharmaceutical cardboard boxes (full and sealed packets). The strengths of the Track & Trace machine are the very compact dimensions to facilitate the installation insertion into existing packaging lines and flexibility: the labeller can be integrated with a special inkjet marker or laser marker for drugs serialization; especially, thanks to the collaboration with the vision systems leading companies in the pharmaceutical market, Pharmatrack Seal 4.0

can install any vision system chosen by the customer satisfying the specific traceability requirements of each country.

The labeling machine can be configured according to the customer’s needs.

The labeling machine belongs to Arca Pharma labeling machines line: a specific line designed and dedicated to the labeling and coding pharmaceutical products.

Therefore, designed to guarantee high standards of quality, safety, productivity and accessibility provided by the guidelines on good pharmaceutical manufacturing practices.

PHARMASEAL 4.0

Tamper Evident Labelling System

Automatic industrial pharmaceutical labelling machine designed to meet the requirements of tamper-evident labelling within operating pharmaceutical packaging lines by applying one or two tamper-evident seal labels on pharmaceutical formed cardboard boxes.

Very compact labeling system that can be used both offline and online connected to other packaging machines (e.g. filling machines) for applications up to 300 pieces per minute.

The labeling machine belongs to Arca Pharma labeling machines line: a specific line designed and dedicated to the labeling and coding pharmaceutical products. Therefore, designed to guarantee high standards of quality, safety, productivity and accessibility provided by the guidelines on good pharmaceutical manufacturing practices.For product traceability, the labeling system can be integrated with an Inkjet marker or a laser marker designed by Arca. The laser marker guarantees considerable advantages in terms of performance (non-stop solution), efficiency and operating savings.

CARDBOARD

Automatic industrial pharmaceutical system for labeling (bollino or vignette label) and coding pharmaceutical products such as flat carton boxes/lay-down pharma packets.

This system can be equipped with labelling machines and print unit providing for carton feeding, labelling and printing of flat boxes as well as with vision systems for reading and checking data.

The labeling machine belongs to Arca Pharma labeling machines line: a specific line designed and dedicated to the labeling, coding, traceability and serialization of pharmaceutical products. Therefore, designed to guarantee high standards of quality, safety, productivity and accessibility provided by the guidelines on good pharmaceutical manufacturing practices.

Industrial labeling systems - Features

Open frame

The innovative structure of Arca systems. Main bases in square sectioned steel tubing, without paneling. In order to exploit every inch of space, to be able to see, clean, wash and operate without impediment, thanks to the utmost accessibility. With the ARCA CLIP it’s really simple to add or take away components and accessories, change labelers and disassemble parts for repair or servicing; without drilling, without welding and with limited working time and costs.

Crazy for steel

The main bases, stanchions, conveyors and electric installation cabinets are made entirely in steel to guarantee the utmost solidness. No vibrations, no bending. Precise and indestructible systems, intended to last a lifetime. AISI304 stainless steel main bases with shot blasted finish (STEEL) or construction grade steel main bases with metallic grey non scratch epoxy powder finish (IRON). Conveyors, paneling and electric cabinets made of AISI304 stainless steel, with matt finish.

One side adjustment

ONE SIDE adjustment: it allows for working on a single handwheel and from either side of the system. Format changes are quick and guided by numerical references. All the adjustments are unequivocably identified with alphanumerical acronyms, retraceable to “format change” tables.

Brushless motors

No mechanically derived movement, reducing wear and noise, improving precision. Product handling devices controlled by brushless motors; effective, practical and safe:

- constant power thrust at any speed

- no breaches, nor oil leakage

- easy to clean

- suitable even at high room temperatures (50°)

- longer average life cycle and zero maintenance

- no risk of burns (“cold” motors)

Electrical excellence

- License free nonproprietary electronics; readily available “off the shelf”, from anywhere

- shielded cables and metal cable blocks with IP68 grade isolation

- power circuits protected by automatic switch with the possibility for link to alarms

(e.g. component on overcharge) - containment cabinets (with compulsory ventilation) correctly sized, easily accessible

and made in steel for protection against knocks and electromagnetic interference - compliance with Electromagnetic Compatibility Guidelines (EMC 2014/30/CE) and Low Tension (LVD 2014/35/CE)

Advance control logic

Intuitive interfaces with the most advanced features:

- SYNCROSPEED: operating speeds for all product handling devices (spacers,

aligners, lateral and upper stabilizers, wrapping units and adapters) are automatically synchronized to the “master” speed set for the conveyor - on-the-fly adjustments, instantaneous and accurate

- alarm management is carried out according to “positive logic”. The detection of good results from all the checks, rather than of anomalies, also ensures against breakdown of the control device

- QUICK SETUP using “product programs” that memorize

and recall operating settings - ability to Ethernet interface to connect to the enterprise operating system

2014/35/CE) - Analog commands (for simpler systems) are identified with clear and intuitive icons that overcome any language barrier

- The most complete systems are equipped with MMI, a color touch screen. On request also compliant

CFR 21 Part 11 and complete with the most advanced features

Safety for the operators

Safety for the operators as for maintenance technicians:

- in the labelers the rotating disks and spindles have no holes or dangerous openings

- dangerous points are covered, and any gaps are always of less than 8mm / 0.31”.

- thanks to the “local protection”, Arca systems ensure the easiest working.

- “Local” accident proof protection devices also safeguard the completeness of the system and products, in the event of erroneous settings.

Attention to details

No detail is left to chance:

- product guides, made in non scratch white polythene with very smooth sliding

- spirit level for easier positioning of the system

- wires and cables are fed inside the metal structure

- working level height adjustable at the installation stage

- acoustic/LED lamp luminous signals, longer lasting and with more intense colors

Color code logic conforming with the EN60204 standard

Industrial labeling systems - Features

Open frame

The innovative structure of Arca systems. The innovative structure of Arca systems. Main bases in square sectioned steel tubing,

without paneling. In order to exploit every inch of space, to be able to see, clean, wash and operate

without impediment, thanks to the utmost accessibility. With the ARCA CLIP it’s really simple to add or

take away components and accessories, change labelers and disassemble parts for repair or servicing;

without drilling, without welding and with limited working time and costs.

Crazy for steel

The main bases, stanchions, conveyors and electric installation cabinets are made entirely

in steel to guarantee the utmost solidness. No vibrations, no bending. Precise and indestructible systems,

intended to last a lifetime. AISI304 stainless steel main bases with shot blasted finish (STEEL)

or construction grade steel main bases with metallic

grey non scratch epoxy powder finish (IRON). Conveyors, paneling and electric cabinets made of AISI304 stainless steel, with matt finish

One side adjustment

ONE SIDE adjustment: it allows for working on a single handwheel and from either side of the system.

Format changes are quick and guided by numerical references. All the adjustments are unequivocably identified

with alphanumerical acronyms, retraceable to “format change” tables

Brushless motors

No mechanically derived movement, reducing wear and noise, improving precision

Product handling devices controlled by brushless motors; effective, practical and safe:

- constant power thrust at any speed

- no breaches, nor oil leakage

- easy to clean

- suitable even at high room temperatures (50°)

- longer average life cycle and zero maintenance

- no risk of burns (“cold” motors)

Electrical excellence

- License free nonproprietary electronics; readily available “off the shelf”, from anywhere

- shielded cables and metal cable blocks with IP68 grade isolation

- power circuits protected by automatic switch with the possibility for link to alarms

(e.g. component on overcharge) - containment cabinets (with compulsory ventilation) correctly sized, easily accessible

and made in steel for protection against knocks and electromagnetic interference - compliance with Electromagnetic Compatibility Guidelines (EMC 2014/30/CE) and Low Tension (LVD 2014/35/CE)

Advance control logic

Intuitive interfaces with the most advanced features:

- SYNCROSPEED: operating speeds for all product handling devices (spacers,

aligners, lateral and upper stabilizers, wrapping units and adapters) are automatically synchronized to the “master” speed set for the conveyor - on-the-fly adjustments, instantaneous and accurate

- alarm management is carried out according to “positive logic”. The detection of good results from all the checks, rather than of anomalies, also ensures against breakdown of the control device

- QUICK SETUP using “product programs” that memorize

and recall operating settings - ability to Ethernet interface to connect to the enterprise operating system

2014/35/CE) - Analog commands (for simpler systems) are identified with clear and intuitive icons that overcome any language barrier

- The most complete systems are equipped with MMI, a color touch screen. On request also compliant

CFR 21 Part 11 and complete with the most advanced features

Safety for the operators

Safety for the operators as for maintenance technicians:

- in the labelers the rotating disks and spindles have no holes or dangerous openings

- dangerous points are covered, and any gaps are always of less than 8mm / 0.31”.

- thanks to the “local protection”, Arca systems ensure the easiest working.

- “Local” accident proof protection devices also safeguard the completeness of the system and products, in the event of erroneous settings.

Attention to details

No detail is left to chance:

- product guides, made in non scratch white polythene with very smooth sliding

- spirit level for easier positioning of the system

- wires and cables are fed inside the metal structure

- working level height adjustable at the installation stage

- acoustic/LED lamp luminous signals, longer lasting and with more intense colors

Color code logic conforming with the EN60204 standard

Global Service

Arca labeling systems are supplied with all the services:

- installation and user training courses, worldwide

- accurate instruction manuals, complete with electric and pneumatic diagrams

- Pre-Delivery Inspection and FAT/SAT validation procedures

- 12 months (renewable and possibly “on site”) guarantee also on the electric components

- preventive maintenance contracts

- technical service carried out from three service centers in Italy (with spares stock), in Milan, Rome and Padua

- worldwide distributors for technical and sales local support.

Download our catalogue

Discover the most suitable industrial labeling machines for your need and all our products.