SOFTWARE 5.0 FOR IDENTIFICATION

State-of-the-art computer programs, adapted to the most demanding industrial contexts and perfectly integrated with hardware of unmatched reliability. Arca masters all aspects of the subject: it not only designs and manufactures identification software, but also state-of-the-art print apply labelers that integrate the best printing devices (Sato and Zebra) and supplies carefully selected consumables (self-adhesive labels and thermal transfer ribbons). A complete solution, with one manager, for projects destined for success!

SOFTWARE 5.0 FOR IDENTIFICATION

State-of-the-art computer programs, adapted to the most demanding industrial contexts and perfectly integrated with hardware of unmatched reliability. Arca masters all aspects of the subject: it not only designs and manufactures identification software, but also state-of-the-art print apply labelers that integrate the best printing devices (Sato and Zebra) and supplies carefully selected consumables (self-adhesive labels and thermal transfer ribbons). A complete solution, with one manager, for projects destined for success!

Label printing and management

Intelligently design the label layout and securely populate it with automatically imported variables. Verify, authorize and distribute labels in the various revisions. Arca offers, integrates and customizes Nice Label: the absolute leader in label printing software for the manufacturing world. International (multilingual), standardized, continuously evolved and supported programs worldwide. From the simplest for stand-alone use, to the powerful LMS, an ideal platform for optimizing mission critical labeling in structured organizations. Nice Label programs, customized and integrated by Arca, guarantee:

- Cloud solutions ideal for managing decentralized operations (distributed factories and subcontractors)

- Microsoft Active Directory compliant user profiling

- SAP and Oracle compatibility certification

- all the most advanced functions that simplify users‘ activities, making them autonomous and freeing up computing resources.

Arca provides the added value: requirements analysis and identification of the ideal architecture, possible customization (Arca Form, Change, Serializer), installation and start-up, training and validation services (Installation Qualification and Operation Qualification).

Label printing and management

Intelligently design the label layout and securely populate it with automatically imported variables. Verify, authorize and distribute labels in the various revisions. Arca offers, integrates and customizes Nice Label: the absolute leader in label printing software for the manufacturing world. International (multilingual), standardized, continuously evolved and supported programs worldwide. From the simplest for stand-alone use, to the powerful LMS, an ideal platform for optimizing mission critical labeling in structured organizations. Nice Label programs, customized and integrated by Arca, guarantee:

- Cloud solutions ideal for managing decentralized operations (distributed factories and subcontractors)

- Microsoft Active Directory compliant user profiling

- SAP and Oracle compatibility certification

- all the most advanced functions that simplify users‘ activities, making them autonomous and freeing up computing resources.

Arca provides the added value: requirements analysis and identification of the ideal architecture, possible customization (Arca Form, Change, Serializer), installation and start-up, training and validation services (Installation Qualification and Operation Qualification).

Installation Qualification

Together with the LMS software, the customer can take advantage of the Installation Qualification service to be conducted in parallel with the installation, directly in the production environment or in a test environment (if requested by the customer). Verify the functionality of NiceLabel-LMS Enterprise software. The activity includes the preliminary preparation of the documentation (at Arca), in Italian.

Operation Qualification

The customer has the possibility to purchase one or more days of Operation Qualification to verify the functionality and compliance with the agreed specifications of the identification software. The validation relates to the operating cycle created for the specific customer, illustrated in the detailed analysis (use of specific “forms” and custom procedures, specifically created for the customer) and includes the documentation necessary for the formalization of the tests conducted, carried out in Italian.

Installation Qualification

Together with the LMS software, the customer can take advantage of the Installation Qualification service to be conducted in parallel with the installation, directly in the production environment or in a test environment (if requested by the customer). Verify the functionality of NiceLabel-LMS Enterprise software. The activity includes the preliminary preparation of the documentation (at Arca), in Italian.

Operation Qualification

The customer has the possibility to purchase one or more days of Operation Qualification to verify the functionality and compliance with the agreed specifications of the identification software. The validation relates to the operating cycle created for the specific customer, illustrated in the detailed analysis (use of specific “forms” and custom procedures, specifically created for the customer) and includes the documentation necessary for the formalization of the tests conducted, carried out in Italian.

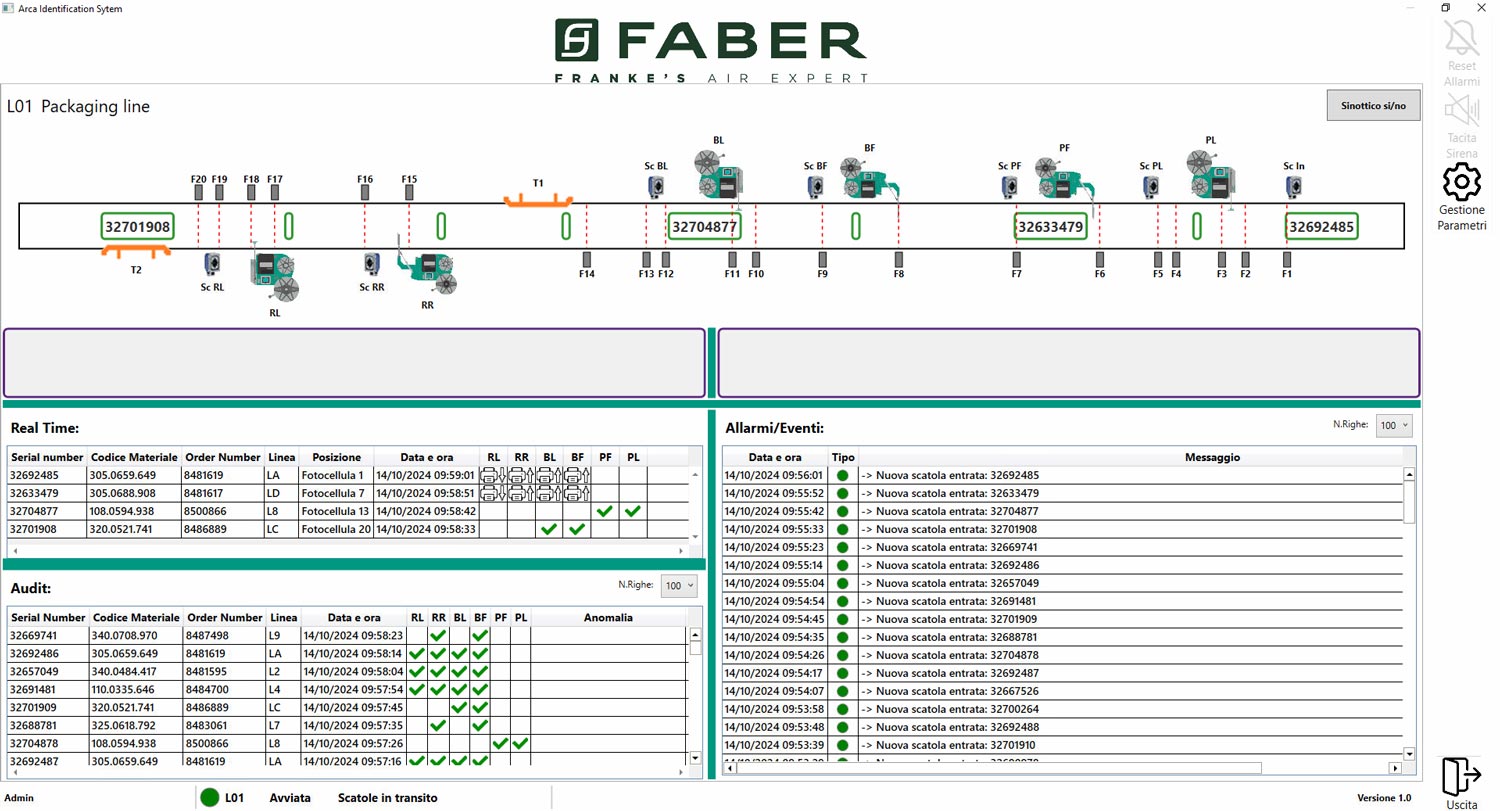

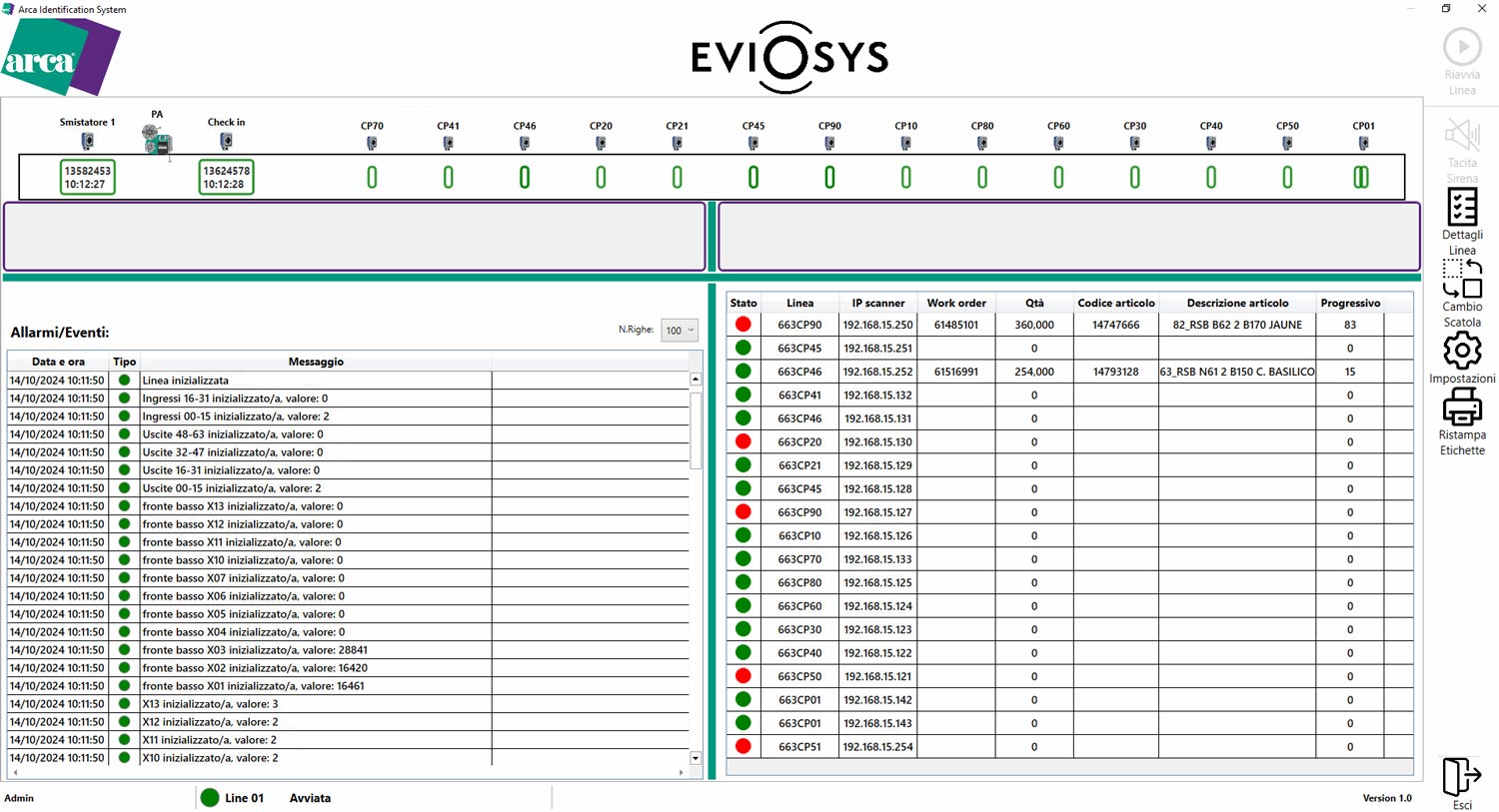

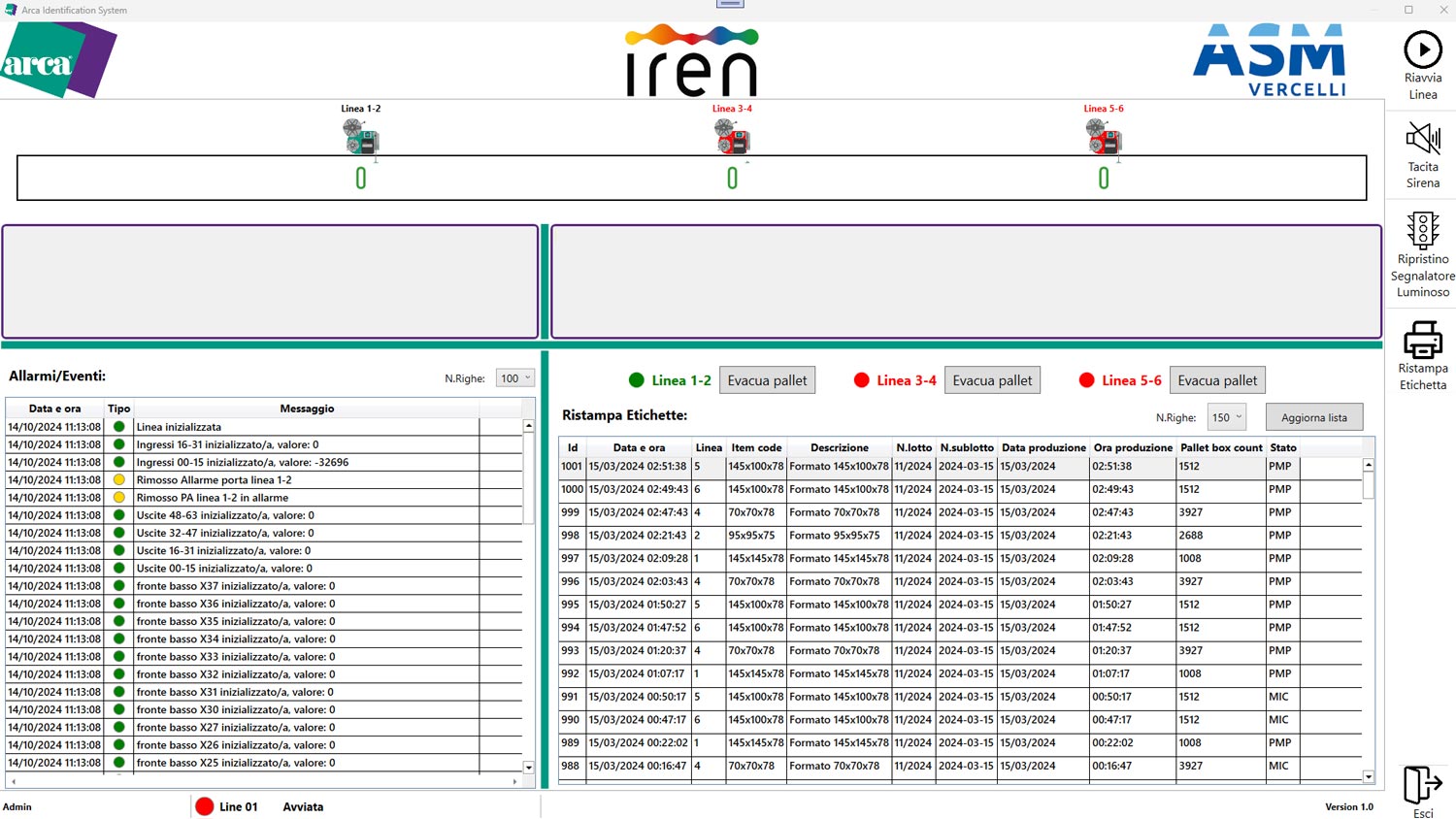

Unattended labeling and marking

Efficient, low manpower processes for the identification of unit, and multiple packages, down to the pallet (Pallet GS1). The Arca Device Automation software platform enables centralized management of all machines used in the process, at all points of the production and packaging line: Non Stop labelers, markers, vision systems and sensors. Arca identification systems employ only Ethernet-connected and “transparent” hardware, thanks to embedded communication protocols that ensure seamless integration with software and the field (weights, probes, codes detected on the line).

Quality control and traceability

Through integration with code readers and vision systems, the Arca Device Automation software platform enables package validation, by:

- quality controls of printed codes

- anti-framing controls

- labeling checks

- Product traceability (unit or multiple packages) by production lot/order

All with accurate reports that enable the identification and monitoring of critical issues in the process.

Integration 5.0 to customer information systems (and beyond)

All software provided by Arca can be fully integrated with the customer’s data bases, web services and PLCs (regardless of the data format used). In addition, the Arca Device Automation software platform allows communication to be developed according to standards of particular importance in the market (IKEA Standard). Custom designs for the best data management and to integrate state-of-the-art, reliable and optimized products into each specific production reality.