DISCOVER ARCA LABELING MARKING

COMPANY

ARCA TODAY

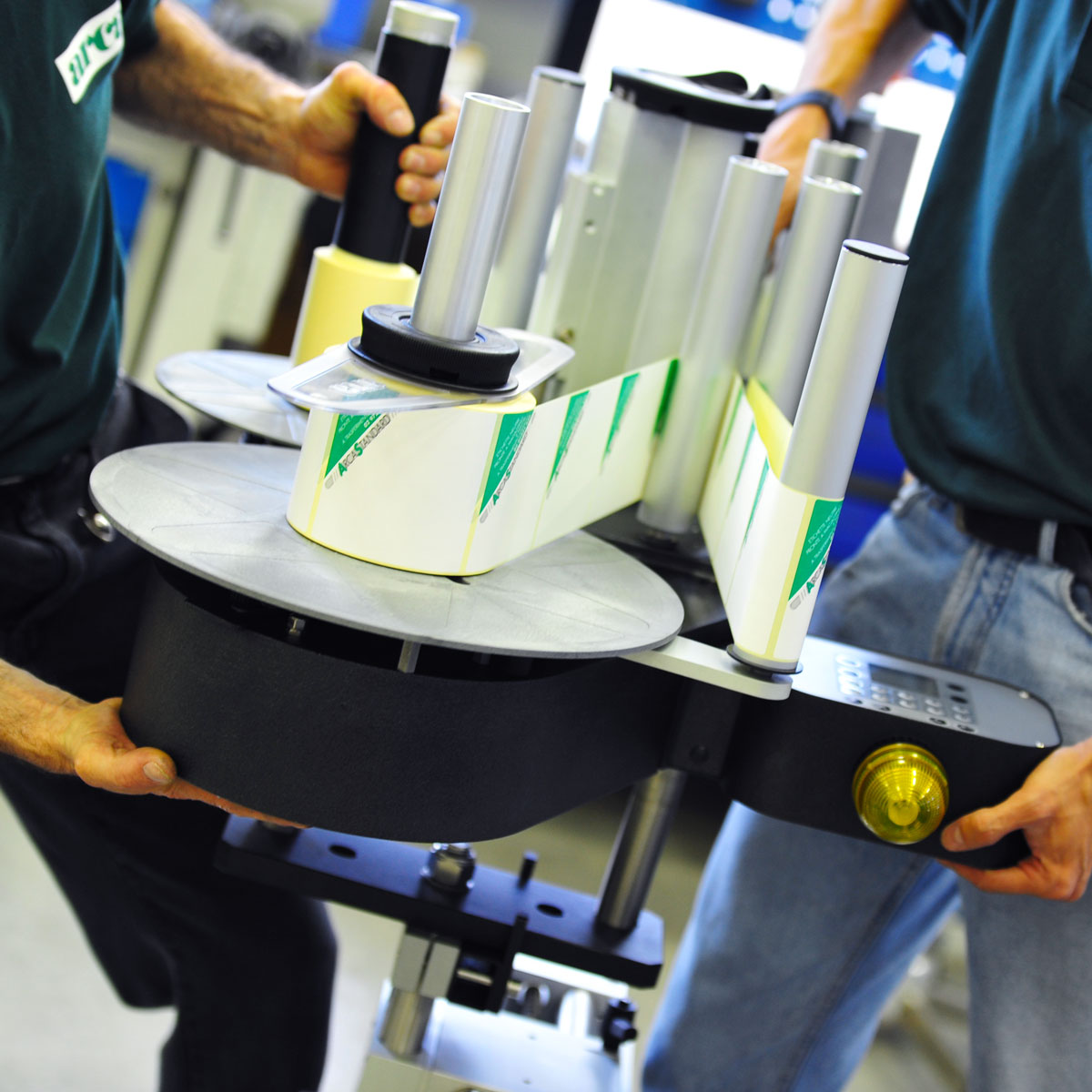

A company that is consistently committed to perfecting its products: advanced machinery that is strictly EC certified, complete user manuals, serious and accurate risk analyses. Solid, durable products specially designed for the manufacturing industry. At Arca, we’re geared towards research, investing approximately 5% of our net earnings in R&D, depositing at least one new patent every year.

Our ISO 9001 certified quality system (covering engineering design, production and sales) is based on modern production processes, inspired by theories of “lean production” and total quality. A flexible organization that works hard to satisfy customers, with a clear vision and precise mission.

Specializing in laser marking and labeling, Arca has based its success on a broad network of distributors, active in five continents, operating as systems integrators.

Arca machines are technologically advanced and perfected by standardization, sold worldwide by packaging and identification specialists who are close to their customers and understand their needs, customizing, installing and providing servicing support.

DISCOVER ARCA LABELING MARKING

COMPANY

ARCA TODAY

A company that is consistently committed to perfecting its products: advanced machinery that is strictly EC certified, complete user manuals, serious and accurate risk analyses. Solid, durable products specially designed for the manufacturing industry. At Arca, we’re geared towards research, investing approximately 5% of our net earnings in R&D, depositing at least one new patent every year.

Our ISO 9001 certified quality system (covering engineering design, production and sales) is based on modern production processes, inspired by theories of “lean production” and total quality. A flexible organization that works hard to satisfy customers, with a clear vision and precise mission.

Specializing in laser marking and labeling, Arca has based its success on a broad network of distributors, active in five continents, operating as systems integrators.

Arca machines are technologically advanced and perfected by standardization, sold worldwide by packaging and identification specialists who are close to their customers and understand their needs, customizing, installing and providing servicing support.

How we work

FAST RESPONSE TIME

The market requires maximum reactivity. Arca formulates its offers, even for complex labels, within a few days.

PRODUCTS FOR EVERY BUDGET

The latest technology, as well as simpler, competitive machine models. In all cases… no compromise on quality.

CLEAR SPECIFICATIONS

Based on the customer’s request, Arca formulates extremely detailed concise quotes with 3D drawings of every component.

SERVICE EXCELLENCE

Professionals providing servicing throughout Italy; attentive customer service; qualified technicians. Reliability and prompt response times.

INTEGRATION CAPABILITY

Along with Arca products, we also install the best code readers and vision systems. For detecting, tracking and inspecting.

EXPERTISE

Arca has been in the labeling and marking business since 1948. Almost a century of knowhow and competitive edge to the benefit of our customers.

Who we are

History

Arca was founded in 1948 by Domenico Fadiga, a former officer in the Italian Air Force. The company began manufacturing labels, which at the time were produced in die-cut cardboard. During the ‘60s, Arca was a market leader in promoting the self-adhesive label revolution in Italy. Since then, there has been continuous growth in consolidated turnover (today Arca is a joint-stock company with private capital), as well as in the quality level guaranteed to customers. In 1975, Arca entered the market of labeling machinery, bolstering it with “print and apply” type labelers about a decade later, embracing thermal transfer technology. The company therefore masters both aspects of self-adhesive technology: materials and machines. Over 60 years of experience. A long history of successes: the best start for a promising future!

Vision

The future for Arca is providing increasingly beneficial labeling and marking solutions for the manufacturing industry. For every system installed we dream of making a happy customer. Insuring real benefits for our customers is the only path to successfully creating value for the entire community and all stakeholders involved. We respect both the environment and the aspirations of our business partners and staff at Arca: our precious human capital. Together we’ll contribute to establishing a positive international reputation for our company and for the Italian packaging machinery sector.

History

Arca was founded in 1948 by Domenico Fadiga, a former officer in the Italian Air Force. The company began manufacturing labels, which at the time were produced in die-cut cardboard. During the ‘60s, Arca was a market leader in promoting the self-adhesive label revolution in Italy. Since then, there has been continuous growth in consolidated turnover (today Arca is a joint-stock company with private capital), as well as in the quality level guaranteed to customers. In 1975, Arca entered the market of labeling machinery, bolstering it with “print and apply” type labelers about a decade later, embracing thermal transfer technology. The company therefore masters both aspects of self-adhesive technology: materials and machines. Over 60 years of experience. A long history of successes: the best start for a promising future!

Vision

The future for Arca is providing increasingly beneficial labeling and marking solutions for the manufacturing industry. For every system installed we dream of making a happy customer. Insuring real benefits for our customers is the only path to successfully creating value for the entire community and all stakeholders involved. We respect both the environment and the aspirations of our business partners and staff at Arca: our precious human capital. Together we’ll contribute to establishing a positive international reputation for our company and for the Italian packaging machinery sector.

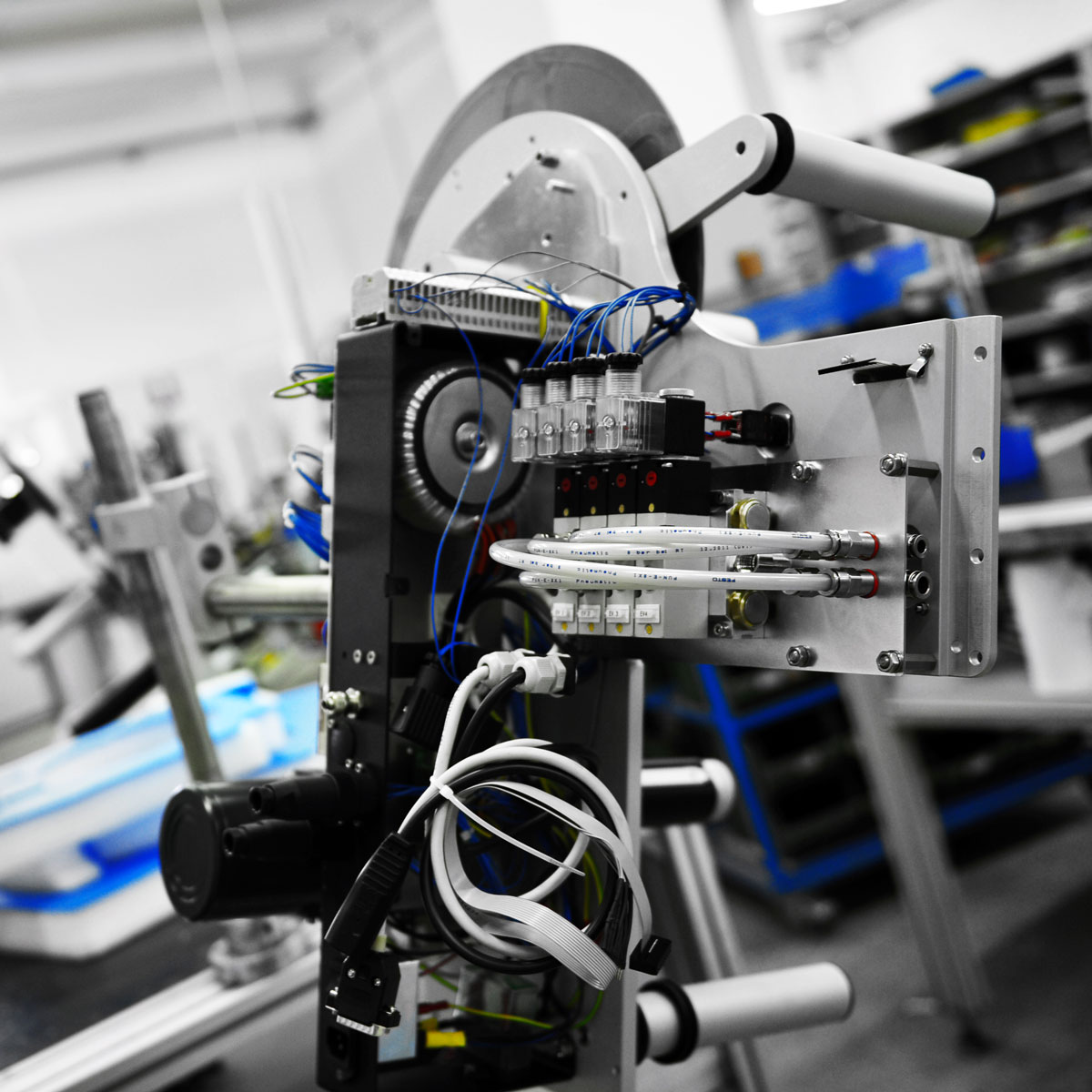

Mission

We design and manufacture labelers, laser markers and thermal transfer print apply units. Advanced machines that are safe, performing, and built to last. We integrate the best technologies for automatic identification that we control with our software for printing, for unmanned labeling, traceability and validation. We supply the manufacturing industry with a broad mix of high quality products and complete solutions. Machines, software and all the most suitable consumables: self-adhesive labels, sleeves, thermal transfer ribbons. A single manager, specialized and expert, to guarantee a sure result

Innovation

Innovating means taking new paths. It costs money and it can happen that you are not understood right away or make a mistake.

And yet, in Arca’s mission, innovation is an attitude. In the 80s Arca adopts the step motor with variable acceleration ramp on the labeling machines.

A few years later, he introduced print apply in Italy. Then AirJet air blow applicators. In the 2000s it launched the Open Frame labeling systems and the automatic labeling machines with vertical architecture. Today there are many innovations offered by Arca: Linerless print apply, High Precision Safe applicators, Scanmanager and Inspector validation devices, Quick Opening device for easy opening, the system for checking the shape of irregular pallets with hills…

At Arca we study, listen, analyze, design, create prototypes and test in search of winning and innovative ideas.

Mission

We design and manufacture labelers, laser markers and thermal transfer print apply units. Advanced machines that are safe, performing, and built to last. We integrate the best technologies for automatic identification that we control with our software for printing, for unmanned labeling, traceability and validation. We supply the manufacturing industry with a broad mix of high quality products and complete solutions. Machines, software and all the most suitable consumables: self-adhesive labels, sleeves, thermal transfer ribbons. A single manager, specialized and expert, to guarantee a sure result

Innovation

Innovating means taking new paths. It costs money and it can happen that you are not understood right away or make a mistake.

And yet, in Arca’s mission, innovation is an attitude. In the 80s Arca adopts the step motor with variable acceleration ramp on the labeling machines.

A few years later, he introduced print apply in Italy. Then AirJet air blow applicators. In the 2000s it launched the Open Frame labeling systems and the automatic labeling machines with vertical architecture. Today there are many innovations offered by Arca: Linerless print apply, High Precision Safe applicators, Scanmanager and Inspector validation devices, Quick Opening device for easy opening, the system for checking the shape of irregular pallets with hills…

At Arca we study, listen, analyze, design, create prototypes and test in search of winning and innovative ideas.

Quality

Total quality management

The quality of machinery begins with the engineering and design phase: scope, requirements, revisions and validation. Everything is documented, in accordance with ISO9001 standards, in order to arrive at a product that guarantees and meets the user’s needs. Hence our design choices: inspired by GAMP norms (Good Automated Manufacturing Practices), ergonomics, easy operation and customization. No unnecessary technical luxuries, but everything’s that’s required to obtain what the customer expects from each product. Today, quality is no longer necessarily weight, thickness and gloss … but rather compliance with specifications. At Arca, excellence is part of our DNA, and perhaps this is the reasons why our machines always have that something extra. Helping your customers earn precious minutes in terms of productivity while guaranteeing safety first and foremost. Machinery Directive 2006/42/EC probably represents the best example of the sum of the details and attention we put in to ensure the safety and health of machine operators. Respecting this logic is imperative. Arca also guarantees the coherent selection of components: the best machinery makes use of top grade components and specially designed quality tested parts. Assembly work is overseen by expert operators who are attentive to every detail, executing their work with passion and pride. Finally, testing phases are conducted by the system’s actual installers, documented with videos and check lists.

The total cost of quality management is nil. And it generates profits, by cutting back on waste, avoiding returns and claims, and above all guaranteeing customer satisfaction. For customers who have chosen Arca

Quality policy

In the effort to assure continuity, solidity and flexibility to our company, we have decided to focus on the Quality of our products, services and processes making this a Strategic Priority. The following is a list of the fundamental rules that will allow everyone to participate in meeting our quality goals:

- The customer must always be satisfied with our services and products.

- For those employees that do not directly deal with external customers, your customer is the employee or internal department to whom you supply a product or offer a service.

- Our employees are our company’s most important asset and must be adequately motivated, allowed to develop skills and trained.

- Everyone in our Company shares the responsibility of improving the quality of our services and products.

- Quality improvement involves continuous effort and planning.

- The suppliers are also one of our Company’s assets and, consequently, must be involved in the quality policy.

- The quality policy must be publicised by all means available.

- The board will provide all the resources necessary to ensure this Quality policy is understood, maintained and improved at all levels of our company .

Certifications

ISO 9001

Some independent, specialized organisations are qualified to state, on the basis of continual checks, that the company’s quality system effectively conforms to the ISO standards. This conformity certification constitutes formal recognition of a qualitative and organisational standard, capable of properly satisfying market demand. Arca has held the ISO 9002 certificate, regarding sales and production, since 1992. This is the best guarantee of producs conformity to agreed specifications. In January ’98 Arca was awarded the certificate of conformity to the ISO 9001 standard design regarding. This gives our customers a further guarantee that our products are suitable for the intended use. Not all certifications are the same! Arca also work with international customers and has requested, and obtained, certification by the British Standard Institution (B.S.I.), the organisation which originally drew up the BS 5750 standards, which later became ISO (International Standard Organisation).

ISO 45001

For any company, the health and safety of its employees is a priority and strategic goal. That’s why Arca has voluntarily implemented a safety system that meets ISO 45001 criteria, obtaining certification from a third party entity, for both its production divisions: Labels and Systems. rca’s commitment to workers’ health and safety in this area can be summed up as follows:

- To act responsibly, in compliance with all regulations and provisions of the law.

- To pursue ongoing improvement for its safety standards, defining specific objectives and verifying their achievement.

- To involve staff by promoting responsibility towards safety management, according to their specific skills.

- To prevent accidents and occupational illnesses in the workplace, through risk assessment, specific training and work processes.

- To ensure the correct application of technologies used and, compatibly with available resources, adopt technologies and processes that allow for and promote the improvement of performance standards in terms of safety and health in the workplace.

- To periodically re-assess this safety and health policy.

Not all certifications are alike! With an international customer base, Arca has obtained its safety system certification from the prestigious British Standard Institution (B.S.I.). Safety first!

Sustainability

Our commitment for the environment

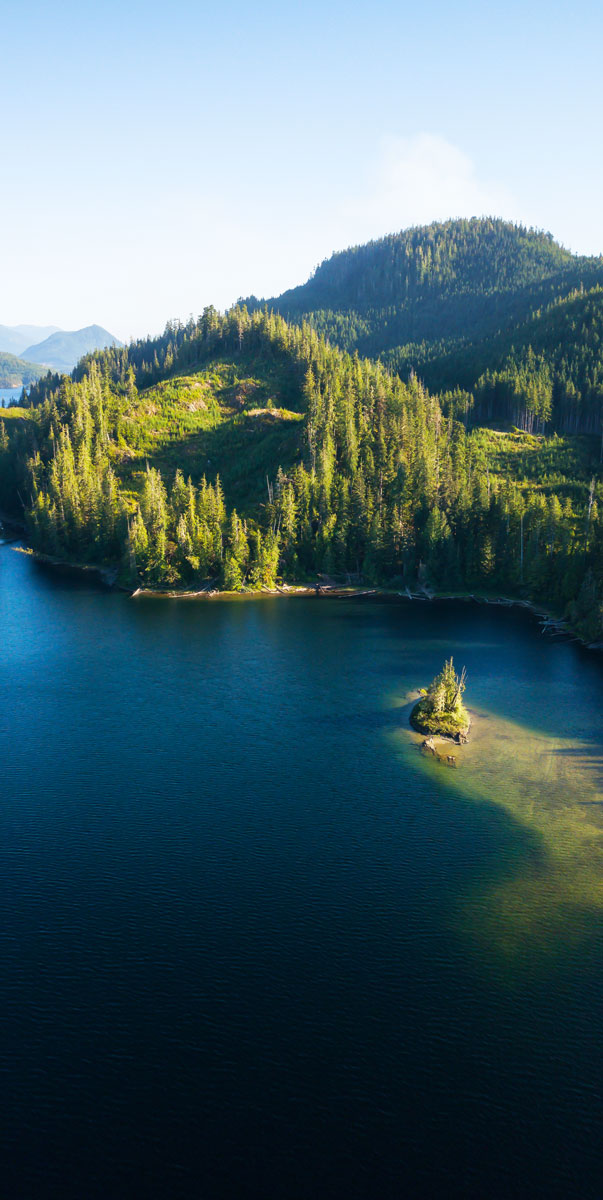

We at Arca Labeling & Marking are aware that a professional, responsible and modern company plays an important role not only for its customers, employees and collaborators, but also for the socio-economic fabric and the territory in which it carries out its daily operations.

Our commitment to sustainability arises from the love for our birthplaces where every one of us leads their professional and private lives.

For these reasons we support with enthusiasm some initiatives for the protection and the development of our territory and invest in internal projects aimed at a constant reduction of the environmental impact of our production activities, as well as in mindful choices in the selection of materials and suppliers.

Operating in a sustainable way is for Arca Labeling & Marking a necessity felt by all company levels and actualized through tangible initiatives.

We at Arca Etichette believe that sustainability is the cornerstone for building our future: it is now unthinkable to live, move and work to the detriment of the environment. Arca has always shared these values and today we confirm it with an important choice: our offices are now powered by clean energy.

Arca Etichette is a benefit corporation!

An important goal has been reached. By Notary’s Deed on 8 April 2021, Arca Etichette S.p.A. acquired the status of Benefit Corporation.

Being a Benefit Corporation gives evidence of “dual purpose” management which, in addition to profit, pursues specific objectives of common benefit, with the aim of generating a measurable positive impact for community, territory and all stakeholders, in a responsible, sustainable and transparent way.

It is an evolution that allows us to protect our corporate, social and environmental values, strengthening our capacity for growth in the coming years.

We believe that if the Value is not common, it’s not a Value.

Sustainability: always in our DNA

We tell the Arca world with our constant commitment within the many more sustainable projects and activities that we carry out every day.

Corporate

Mission and value of the Arca group

OVER 70 YEARS OF EXPERIENCE

Arca Corporate

The Mission of the Arca group testifies to the commitment to continue and strengthen the leadership of products and services, supported by new commitments towards the Environment, Workers and the Community.

We create innovative products for labeling and identification, intended for the manufacturing industry: self-adhesive labels and sleeve for packaging decoration, promotion, safety, logistics and the best automatic labeling machines, print-apply, laser markers, software for unmanned printing, product validation and traceability. By mastering all aspects of the subject, we can guarantee complete and safe solutions.

We are a Benefit Corporation, committed to generating measurable economic and social value, preserving the environment, using processes that reduce energy consumption and waste of resources, involving suppliers and customers in common actions on ecological issues. We promote projects for our community, spreading the culture of sustainability in the area. We encourage the cultural and professional growth of our collaborators and pursue their gratification, in an environment that fosters creativity and satisfactory well-being for all those who contribute to our mission.

Great Stories Are Born From A Great Passion

We create mutual value for our people, the local communities impacted by our activities, the stakeholders along our value chain and the contexts in which we operate.

Great Stories Are Born From A Great Passion

We create mutual value for our people, the local communities impacted by our activities, the stakeholders along our value chain and the contexts in which we operate.

Code of Ethics

In the process of organizing the Group’s commitment, we have prepared a Code of Ethics which identifies the corporate values in which the company intends to comply. Furthermore, it describes the way of doing business for our companies, based on honesty, responsibility and transparency.

This Code of Ethics is intended for our employees but also for suppliers and collaborators and regulates our behavior towards all stakeholders.